THE TUNNEL SYSTEM

The BBT is actually a complex tunnel system.

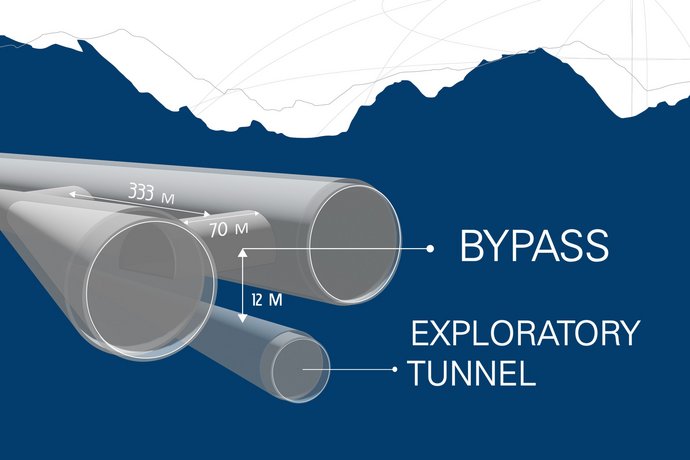

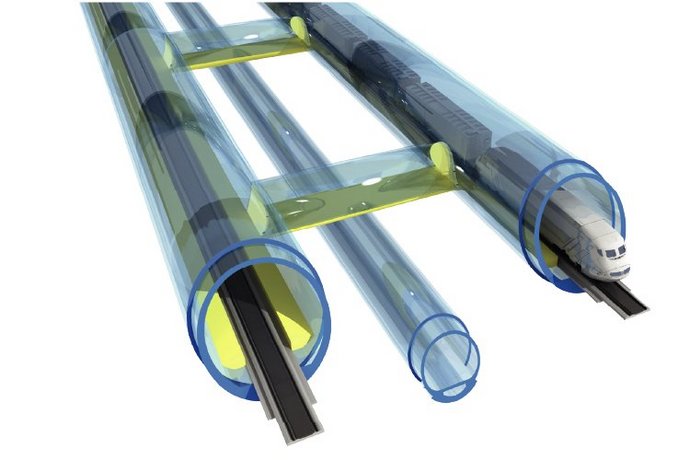

- It consists of two parallel running main tunnel tubes lying between 40 and 70 metres apart. They will be equipped with a single track, allowing trains to run through the tubes in one direction.

- The main tunnels are linked every 333m by cross passages. In the event of an accident, these short tunnels can be used as escape routes.

- A particular characteristic of the Brenner Base Tunnel is the exploratory tunnel, its third tunnel tube, located centrally beneath the two main tubes. During the construction phase, the exploratory tunnel provides information about the rock structure and is used to investigate the geological conditions for the excavation of the main tunnels. During the operational phase of the BBT, the exploratory tunnel will serve as a service tunnel for water drainage and maintenance activities regarding the numerous technical structures located in the tunnel.

- The tunnel system is completed by access tunnels, emergency stops, crossover points, connecting tunnels and a rescue tunnel.

Lateral access tunnels in Ampass, Ahrental, Wolf bei Steinach am Brenner and Mules connect the BBT with the outside world.

Smaller cross passages connecting the two main tubes are located every 333 m.

In case of unforeseen events, trains can use the safe underground emergency stops (Innsbruck, St. Jodok, Trens).

Here, trains can switch to the other tunnel tube and thus change to the other track if necessary.

HOW IS THE BBT BEING BUILT?

The choice of tunnelling method depends on the geological conditions of the rock, geotechnical findings and forecasts, as well as construction logistics and economic considerations. The length of the route to be excavated and the available construction time both influence the choice of excavation method.

So some sections of the tunnel are excavated by drilling and blasting whilst others are built using mechanical construction methods, i.e. with a tunnel boring machine (TBM).

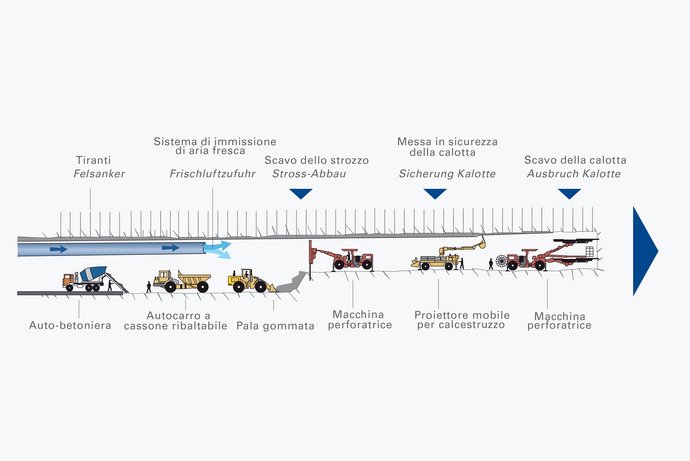

DRILL AND BLAST

Drill & blast is a flexible tunnelling method. It is suitable for difficult and changing rock conditions as well as for different and complex cross-sectional geometries. The stages for drilling and blasting, on the other hand, are predetermined. First, blast holes are drilled. These are filled with explosives, and then the blast is carried out. After the excavated material has been removed, the excavation is stabilised with shotcrete, anchors, lattice arches and structural steel mats. Once a blasting cycle is complete, the process starts again from the beginning.

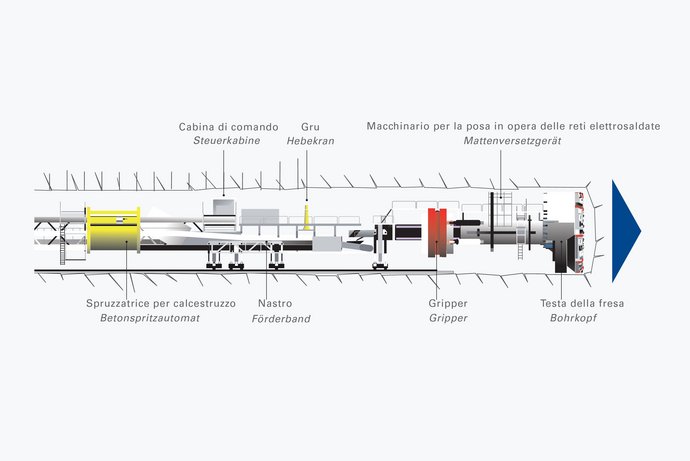

MECHANICAL EXCAVATION

Tunnel boring machines (TBMs) are our ‘giants in the mountain’. They drill through the rock with a rotating drill head and secure the engineering works with anchors, reinforced rods and shotcrete (see diagramme) or by installing precast concrete elements, the so-called tubbing rings. The advantage of mechanical excavation lies in the high daily production rate. The most important part of the TBM, which is actually a high-technology underground logistics plant, is its cutter head. This has a diameter of several metres and consists of several cutter bits that press against the rock and break it into small pieces. The trailing structure behind the drilling head, or back-up, ensures the supply of the tunnelling equipment and the disposal of the excavated material. The machine also includes rock stabilisation, ventilation and dust collection equipment.

A RAILWAY SYSTEM?

After the tunnel has been excavated and the inner shell has been installed, all the equipment necessary for railway operations will be installed. This includes tracks and overhead lines as well as signalling technology.

![[Translate to EN:] Sprenglöcher werden gebohrt](/fileadmin/_processed_/7/0/csm_Sprengl%C3%B6cher_bohren_b1f8fb3e2c.jpg)

![[Translate to EN:] Einfüllung der Löcher mit Sprengstoff](/fileadmin/_processed_/b/a/csm_Sprengstoff_einf%C3%BCllen_7ea9617a0f.jpg)

![[Translate to EN:] Laden und Sprengen](/fileadmin/_processed_/f/f/csm_Sprengung_215ef112e8.jpg)

![[Translate to EN:] Schuttern](/fileadmin/_processed_/e/5/csm_Schuttern_12948789ce.jpg)

![[Translate to EN:] Ausbruchssicherung](/fileadmin/_processed_/8/4/csm_Ausbruchssicherung__076fbf20c3.jpg)

![[Translate to EN:] Rohbaussicherung](/fileadmin/_processed_/e/f/csm_scavo_tbm-02_d72e4683c3.jpg)

![[Translate to EN:] Maschinenband](/fileadmin/_processed_/0/2/csm_scavo_tbm-03_b48215a2c2.jpg)

![[Translate to EN:] Steuerstand der Tunnelbohrmaschine](/fileadmin/_processed_/6/7/csm_scavo_tbm-04_d479127979.jpg)

![[Translate to EN:] Montagekaverne](/fileadmin/_processed_/d/c/csm_scavo_tbm-01_67ac4cce87.jpg)