THE CONSTRUCTION LOT IN FIGURES

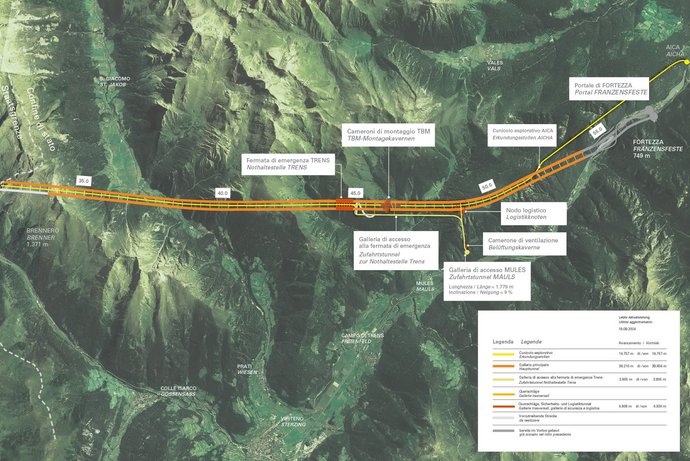

This construction lot involves the construction of 65 kilometres of tunnel.

...of which approx. 40 km are main tunnels.

...and approx. 15 km are exploratory tunnels.

Cross passages connect the two main tunnels every 333 metres

Executive construction consortium: Brenner Tunnel Construction (BTC): Webuild S.p.A., Ghella S.p.A., Oberosler Cav Pietro S.r.l. (bis Juni 2018), Cogeis S.p.A. PAC S.p.A.

Contract value: 993 million EUR

CURRENT WORK

Work is currently underway in the main west tunnel to install the inner lining.

In addition, tunnelling work and the installation of the inner lining are being carried out in the cross passages between the two tunnel tubes.

The inner lining is currently being installed in the section of the exploratory tunnel that has been excavated using conventional mining techniques.

EXCAVATION DATA

- Excavation 3.805 m

- Length 3.805m

- Cross-section 80 m²

- Excavation 39.187 m

- Length 39.950 m

- Cross-section 85 m²

- Excavation 14.813 m

- Length14.813 m

- Cross-section 35 m²

- Excavation 5.583 m

- Length 6.394 m

- Cross-section 26-56 m²

COMPLETED WORK

- Construction of a tunnel between the Mules access tunnel and the Trens emergency stop

- Drill and blast excavation of the two main tunnels southwards

- Excavation of the exploratory tunnel northwards with TBM Serena

- Breakthrough between construction lots H61 Mules and H71 Isarco river underpass

- Excavation of the main tunnel east northwards with TBM Virginia

- Excavation of the main tunnel west northwards with TBM Flavia

EXCAVATION METHODS

The two main tunnels east and west as well as the exploratory tunnel northwards (Innsbruck) are being excavated mechanically, i.e. with tunnel boring machines (TBM). The two main tunnels and the exploratory tunnel southwards, the access tunnel to the Trens emergency stop, the emergency stop itself, as well as the cross passages and the safety and logistics tunnels are being constructed using traditional mining methods, i.e. drill and blast.

MECHANICAL EXCAVATION: Mechanical excavation began in 2018: In May, the Serena tunnel boring machine set off on its approximately 14-kilometre journey through the exploratory tunnel heading north to the state border at Brenner, which it reached in November 2021. In spring 2019, the two TBMs Virginia and Flavia started their journey north towards Brenner in the 14-kilometre-long east and west main tunnels respectively. While Virginia reached the Brenner Pass in March 2023, Flavia arrived at the national border in May 2025.

DRILL AND BLAST EXCAVATION: Mining operations towards the south began in April 2017 and were completed in October 2020 for both main tunnels.

SPECIAL FEATURES OF THE CONSTRUCTION LOT

Compared to the other construction lots, this lot has the longest distance driven by machine. A total of around 42,700 metres of tunnel were driven with the three TBMs in this construction lot. More than 170,000 tubbing segments and 35,000 base tubbing segments were produced in the specially constructed segment factory in Hinterrigger for the inner lining of these sections.

Due to the size of the construction lot, logistics presented the greatest challenge. A tubbing factory was built on site to produce the large number of segments required. By optimising many steps, such as transporting the segments into the tunnel by rail using a service train, these precast concrete elements were delivered to the tunnel boring machines by rail rather than by lorry. These were then installed as the inner lining of the tunnel. Each train transported two rings, i.e. 14 tubbing segments. This made it possible to avoid traffic congestion on the SS12 road and implement an environmentally friendly solution at the same time.

Around 30% of the excavated material from construction lot Mules 2–3 was reused for the production of the tubbing segments – a concrete and efficient example of successful circular economy.